Capping cylinder solution saves time, energy and money

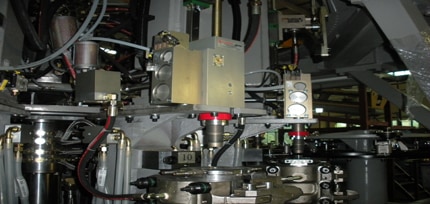

Tech-long is the largest filling and blowing machinery manufacturer in China. They required a new compact stretch blowing module together with capping cylinder and pilot valves and able to produce 1,800 PET bottles per hour.

Norgren designed a capping cylinder which operates in two stages to precisely control the pre-forming process, then flow the 40 bar high pressure to blow the bottle. The solution helps the customer use less air, saving energy which was an important benefit as increasingly more beverage customers demand environmentally friendly suppliers.

The solution further increases output by 20%, meeting the 1,800 bottle per hour target that was required and also makes maintenance easier due to its compact design, reducing the overall maintenance costs.