CCI upgrade extends productivity at leading agricultural processing facility

Requirement

Archer Daniels Midland (ADM) is one of the world’s leading agricultural processors. For nearly 10 years, excessive and uncontrolled flow velocities within the boiler system at their Illinois HQ have caused erosion, increased vibration and have compromised performance.

To maintain levels of control and productivity, valves were regularly replaced and complete maintenance procedures undertaken at great cost. ADM asked CCI’s Valve Doctor Team to assess flaws in the system design and determine a cost-effective solution.

Solution

Historical data on repairs, spare part and labour costs, and loss of performance estimates gave a unique insight to the operating conditions at this site. The results led the Valve Doctor team to recommend installing nine feedwater control valves and eleven spraywater valves using CCI’s DRAG® technology.

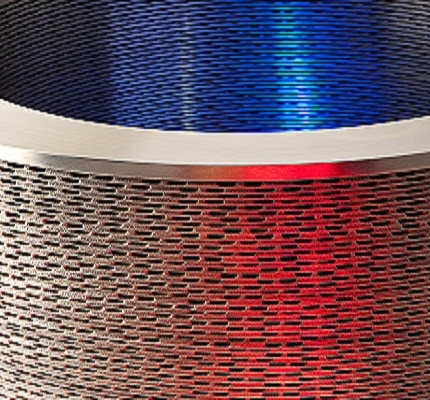

The bespoke tortuous flow paths in the heart of the valve (disk stack) have reduced exit velocity which eliminates valve erosion damage whilst reducing the pressure drop on each stage.

Installation of the DRAG spraywater and feedwater control valves helped ADM significantly reduce maintenance costs by removing erosion and excess vibration. Following the installation of CCI’s valves, maintenance intervals are expected to extend from 18 months to five years and provide added control and dependability to increase productivity.